Top 10 Principles for a Supply Chain Operating Model

Over the past few decades, globalization has inarguably merged with commerce. Large corporations originally expanded to source labour and components from emerging nations, then as they increased their wealth and purchasing power, they began to sell in those same nations.

Supply chains have become increasingly complex because of keeping up with demand, travelling through various nations to procure commodities most practically and economically.

To guarantee that everyone knows what to do, when to do it, and how, supply chain operating models in business are crucial. The operating model is the culmination of all internal business operations for a company.

The Supply Chain Operating Model forbids applying functional silo thinking to the chosen supply chain organization archetype. Essential details like conflict resolution techniques, escalation strategies, and SLAs for internal and external supply chain operations are also included.

57% of businesses think supply chain management gives them a competitive advantage, allowing them to expand their operations. Following COVID-19, 64% of merchants faced difficulties converting their supply chains for online sales.

GrowthJockey assists companies that want to enhance their supply chain management continuously. We accomplish this by striking a balance between the demands of the client and the provision of goods that meet those wants and preferences. This gives the company its competitive advantage, boosts net profits, and manages production costs.

If you want to learn more about the operating model supply chain and the top ten principles of business model, keep reading Growth Jockey's insights.

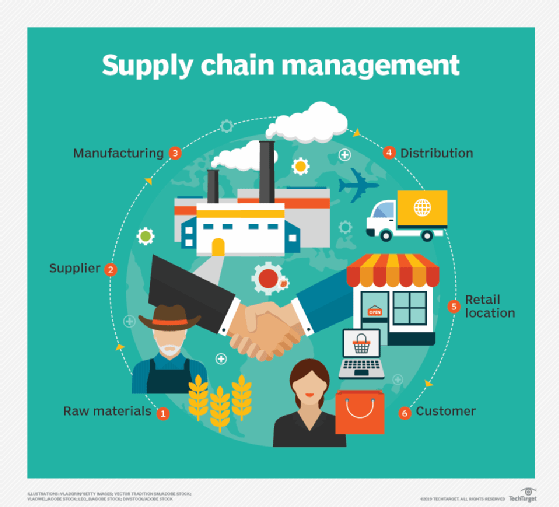

What is Supply Chain Management?

The supply chain is a structure or network that links the many components of your company. It starts with the vendors or manufacturers that make your goods and provide you with the raw materials.

Then it links the several additional phases your product must pass through before it is purchased or used by the final client. It is a network comprising several processes and a wide variety of entities, people, and information.

In other words, the supply chain describes the steps needed to get a product from its starting point to the consumer.

The supply chain management process involves developing and managing all the people, assets, and technology that go into a company's value generation. Price negotiations, production planning, and logistics management impact a company's value equation and are essential supply chain elements.

Many supply chain experts need help to precisely track their activities. The fact that 69% of businesses lack complete visibility into their supply networks is evidence of this.

GrowthJockey assists you in creating a supply chain operating model that will reduce business costs while reducing manufacturing time and waste. We make tracking and managing data easier to address because of our years of experience in this industry and our cutting-edge technological techniques.

Additionally, we'll assist you in identifying areas where you can make more advancements to strengthen your supply chain operation.

The operating model of supply chain and supply chain management is reflected in some principles, and it is now essential to the success of organizations in the modern world. Applying these ten principles will guarantee customer happiness and boost profit growth.

An Amazing Example of Supply Chain Operating Model: Amazon

Amazon's "online big box" concept is the ideal illustration of unconventional supply chain models. Amazon surpassed Walmart as the largest retailer in the world in the past ten years.

Being a platform rather than just a store, Amazon allows for the sale of goods by almost anyone. Because it offers more products than any other online retailer, so people think of it when they shop online.

Then, it offers daily necessities at a discount and undercuts suppliers. Their warehouses heavily utilize automation to group things headed in the same direction so they may be transported immediately.

Finally, its investments in delivery personnel and technology have raised the bar for 2-day shipping and even made same-day delivery possible. Bypassing third-party logistics (3PL), Amazon completes order fulfilment independently.

Principles of Supply Chain Operating Model

Designing a supply chain through processes of operating model, which includes the supply chain's organizational structure, governance, and operations, becomes a more challenging task as businesses grow internationally.

15% of businesses only have visibility into production, while 62% have limited visibility into their supply chains. Meanwhile, 17% claim extensive supply chain visibility, and 6% report complete visibility.

Working with leading corporations worldwide has given GrowthJockey years of experience. Based on our study, we have created a technique that removes the element of guesswork from supply-chain operating model design and aids businesses in putting it into practice.

Below are the top ten principles we follow while building a supply chain operating model for companies.

1. Classification of Customers

Organizing your clients into discrete groups based on their needs and using your supply chain to suit those needs is the first of the supply chain operating model principles. With this division, you can provide better service to each category in terms of revenue and average cost within and across client groups.

GrowthJockey lets you develop your service portfolio to be more adaptable to ongoing changes in demand rate by segmenting clients based on their unique needs. To forecast the profit margin for each section, we also employ more sophisticated analysis techniques, including cluster analysis and factor analysis.

2. Innovation

Supply chains must innovate to adapt as the business landscape rapidly changes. To be competitive, you must continually improve your processes and innovate new ideas.

When a creative remedy for a client's issue is created and accepted, it replaces the previous prevailing paradigm.

3. Defining the Vision

What will add the most value should primarily determine how the operating model is designed. Therefore, the company's concept of value serves as a crucial beginning point.

Although it would seem like an apparent initial step, many CPG companies omit to outline the strategic vision and communicate commercial objectives.

4. Customize Logistics Network

Following consumer segmentation based on various criteria, supply chain managers must modify logistics networks to cater to multiple segments. The manager must order the delivery promptly and make arrangements to distribute the items categorized as urgent.

This rule only applies in some circumstances, though.

5. Align the Team

Establishing a successful supply chain depends on effective cross-business execution. However, all too frequently, each component of the supply chain functions as a separate entity. It is divided by business units, different priorities, differences in time and resources, siloed systems and procedures, geographical boundaries, and even siloed priorities.

6. Maintaining Differentiation

Many companies set their production goals using the conventional method. This involves estimating the future market demand for the finished goods and estimating the time needed to transform raw materials into finished goods.

Numerous techniques exist, including cellular manufacturing and the just-in-time (JIT) production approach.

However, these techniques may present specific challenges, and supply chain management addresses those issues.

7. Developing Right IT Services

Before beginning any IT projects, companies should conduct business process reengineering since they should be undertaken in collaboration. This gives a correct understanding of process deficiencies and aids in identifying the type of innovation required.

8. Establish Alliances

Strong supplier relationships are essential for the success of the supply chain since they frequently result in cost savings and increased dependability. Both parties should gain from these connections if they approach them as partnerships. That necessitates fair problem-solving and jointly developing goals that advance the interests of both parties.

9. Proper Planning

A complete picture of the anticipated pace of demand in the market is provided by demand forecasting, a historical process that depends on the availability of precise and timely information.

The demand forecasting process may encounter several issues because of its practical orientation. The Cross-Functional Planning Process and demand planning tools differentiate the supply chain (DPS).

10. Technology

The way supply chains function has changed because of the rapid development of technology in information processing and the transfer of physical goods. In the past, we would place catalogue orders, send checks by mail, and watch for our deliveries.

Today, we use our phones to make purchases, pay with credit cards, and wait for real-time notifications until our packages are delivered to our homes.

Understanding how technologies function is essential for the supply chain management. Growth Jockey assists businesses in understanding how to use these technologies to add value at each stage of the supply chain.

To Sum Up

For many businesses, the supply chain operating model has become increasingly important. Instead of treating this business area as a cost centre, they view it as a potential competitive differentiator. The ten supply chain management principles listed above facilitate the most effective and economical acquisition of commodities.

Any business' supply chain is essential and runs efficiently by several interrelated parts. If you want your supply chain to function well, you must assess and effectively control supply chain metrics, which refer to all the logistical data we may find in a supply chain.

That is why it is crucial to conduct your research and take assistance from a group of GrowthJockey professionals who can assist you in developing your supply chain solutions.

We know the market is continually evolving to satisfy customers' growing wants. We make supply chain planning fluid and agile to better adapt to these changes. By doing this, your company can stay one step ahead of the competition and guarantee that your clients are happy with the goods and services they receive.

At GrowthJockey, we are fully committed to developing customised operating models that effectively address the critical challenges faced by our clients across various industries. Irrespective of your company's size, whether it's a small-scale enterprise or a large corporation, you can now benefit from our tailored solutions. Take the decisive step towards unlocking the next level of growth for your brand by reaching out to us today!