How AI in Logistics Is Revolutionising Supply Chain Efficiency in 2025

Logistics is the unseen engine of the global economy in this age - it helps in moving goods from manufacturers to consumers.

In this interconnected and advanced world, how well these supply chains function affects the success of your business and consumer experiences. AI in logistics is changing the industry drastically by shifting logistics from a basic operation to an intelligent, autonomous system.

Let’s check out how AI is transforming logistics. We’ll also cover the key technologies involved and how businesses in India and worldwide are using them to stay competitive.

Overview of AI's Transformative Potential in Logistics

AI in logistics is transforming supply chain management, representing a major shift like containerisation did for shipping in the 1950s. Previously, logistics depended on human decisions and manual processes, which were slow to adapt to changes and unexpected disruptions.

AI in logistics importance is increasing, and it's bringing in new capabilities with it. These systems can sense, learn, predict, and act independently throughout the supply chain. According to recent studies, businesses using AI report 66% higher productivity across teams, which can be a significant boost.

Difference Between Traditional vs AI-Driven Logistics

| Aspect | Traditional Logistics | AI-Driven Logistics |

|---|---|---|

| Decision Making | Reactive decisions based on historical data and human judgment | Proactive decisions using real-time data analysis and predictive modelling |

| Planning | Static routing and scheduling with manual adjustments | Dynamic optimisation that continuously adapts to changing conditions |

| Visibility | Limited tracking capabilities with delayed information | Real-time tracking with complete supply chain transparency |

| Inventory Management | Fixed inventory models with periodic reviews | Adaptive inventory optimisation with automatic adjustments based on demand forecasts |

| Resource Utilization | Standard resource allocation regardless of changing needs | Intelligent resource allocation that adapts to fluctuating demands |

| Error Handling | Manual identification and resolution of issues | Automated anomaly detection and preemptive problem resolution |

What is AI in the Context of Logistics?

The way supply lines work is being completely changed by AI, which is shaking up the world of operations. At its core, AI in transport helps computers figure out what's going on around them, make better choices, and act on their own. This means that things like moving things, running stores, keeping track of stock, and taking care of supplies can be done faster and better.

The whole point of AI in transportation is to use different technologies together to get the best results.

Traditional vs AI in Logistics Difference in Automation

Traditional automation is all about following specific rules and doing repetitive tasks without much flexibility. AI, on the other hand, learns and adapts. It makes decisions based on real-time data, predicts what’s likely to happen next, and adjusts accordingly.

This gives companies the ability to react faster and smarter to unexpected AI in logistics challenges, like delays or changes in demand.

Types of AI Used in Logistics

1. Machine Learning (ML):

This is all about teaching systems to start recognising patterns from large data sets. For example, ML can be used to predict how much inventory is needed or optimise delivery routes based on past trends.

2. Computer Vision:

Think of this as giving machines “eyes.” With computer vision, AI can inspect, scan, and sort packages all on its own. Additionally, it may assist in identifying problems, such as damaged items, which can speed up and improve the accuracy of procedures.

3. Natural Language Processing (NLP):

NLP helps AI understand and respond to human language. In logistics, this might look like chatbots that handle customer inquiries or manage real-time tracking information, improving communication and customer service.

4. Predictive Analytics:

By analyzing past data, predictive analytics helps companies forecast future events. For instance, it can predict when shipments might be delayed or forecast demand for certain products, helping businesses plan better.

5. Robotics & Agentic AI:

Robots with agentic AI do actual work in warehouses such as picking, packing, and sorting. They don't need regular instructions from people; these robots decide for themselves how to handle goods and make the best use of space in the warehouse.

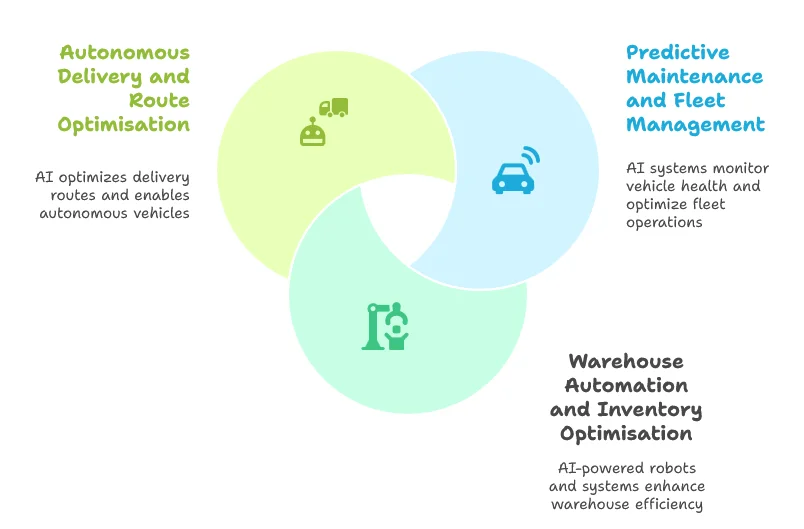

Top 3 Key AI in Logistics Applications

AI offers many opportunities to improve the supply chain. These areas are where AI in logistics brings the biggest improvements and advantages.

1. Predictive Maintenance and Fleet Management

AI-driven predictive maintenance systems monitor vehicle health through sensors that track engine performance and brake wear. These systems analyse data to identify potential failures early, enabling proactive maintenance that prevents costly breakdowns and service disruptions.

The impact of AI goes beyond simple repairs, offering comprehensive fleet optimisation. It calculates the best vehicle replacement cycles based on actual usage, improves fuel efficiency by analysing driving behaviour, and enhances driver performance with tailored training recommendations. Companies using these systems report remarkable results.

2. Warehouse Automation and Inventory Optimisation

Modern warehouses use AI-powered autonomous mobile robots (AMRs) to navigate and pick items without human help. These robots learn the best paths through reinforcement learning algorithms, adapting to changing warehouse layouts and reducing labour costs. They also improve picking accuracy over manual methods.

AI-powered inventory systems predict demand for thousands of SKUs by analysing patterns, such as seasonality, market trends, and weather. This enables businesses to manage inventory efficiently, reducing storage costs and keeping just the right amount of stock to fulfil customer orders.

3. Autonomous Delivery and Route Optimisation

AI in logistics excels at optimising last-mile delivery through advanced solutions. Route planning algorithms analyse multiple factors, including traffic patterns, delivery windows, and package characteristics, to make optimal decisions. These systems continuously update routes in real time, reducing delivery times and fuel consumption and boosting driver productivity.

Autonomous delivery vehicles are transforming how we think about logistics. Self-driving trucks are growing more reliable for long-distance hauls, while delivery drones offer speedy solutions in urban areas. These systems use advanced AI, like computer vision for navigation, reinforcement learning for smart decision-making, and predictive analytics to plan efficient routes.

AI in Logistics Case Studies in the Real World

One of the best AI in logistics examples comes from Maersk - a leading name in the shipping industry.

The company faced hurdles such as rising costs and competition. To overcome these, Maersk started changing their digital strategies, putting AI at the centre of it for maximum results.

They deployed advanced AI-powered predictive analytics with multiple capabilities. These systems monitor global shipping conditions by integrating data on weather patterns, port congestion, and equipment availability. This enables proactive decision-making, rerouting ships to avoid delays, optimising fuel consumption, saving costs, and improving delivery reliability worldwide.

Maersk has enhanced warehouse efficiency by adopting AI and computer vision, improving sorting and inventory picking. These advancements are part of their strategy to simplify logistics and supply chain operations through technology.

AI in Logistics Benefits: How is it Improving Supply Chain Efficiency

Understanding the advantages of AI helps organisations make smarter investment decisions. These AI in logistics benefits prove that it is more than just about cost savings; it’s a driver of real business transformation.

1. Enhanced Supply Chain Visibility

AI-powered tracking solutions provide organizations with unprecedented access to their supply networks. They enable you to follow commodities' movements in real time over worldwide networks with pinpoint precision. By pulling data from GPS trackers, warehouse systems, and transport operators, these systems provide valuable insights to decision-makers.

2. Significant Cost Reduction

AI in logistics drives cost savings across different areas. It improves fuel efficiency with smart route planning, increases labour efficiency through automation, and reduces inventory costs by accurately forecasting demand.

3. Improved Customer Experience

AI-enabled logistics enhances the customer experience by offering accurate delivery predictions and managing potential disruptions before they affect the journey. They also provide personalised services tailored to each customer's preferences. Today’s customers expect precise delivery times and comprehensive real-time tracking, not vague delivery windows.

3 Challenges & Limitations of AI in Logistics

Despite its transformative potential, this change presents significant challenges that organisations must address during AI in logistics implementation. Recognising these obstacles is key to creating realistic timelines and developing effective risk management strategies.

1. Data Quality and Integration Issues

AI systems rely on high-quality data from the entire supply chain to work effectively. Many organisations struggle with fragmented systems and inconsistent data formats. Information silos between departments also complicate matters, requiring significant groundwork before AI in logistics implementation.

2. AI in Logistics Implementation Costs and ROI Concerns

For a majority of the companies, especially small and medium enterprises, the initial investment in AI for logistics can be a tough barrier. The costs include technology acquisition, infrastructure upgrades, and staff training. These expenses can add up quickly.

3. Workforce Transition and Skill Gaps

Implementing AI successfully means making significant changes to the workforce. Companies need to invest in reskilling existing employees and hire new talent for specialised roles. Managing resistance to new technologies is also a big challenge that many logistics companies have not yet figured out.

Emerging AI in Logistics Trends to Look For

AI is quickly transforming logistics, and new trends are emerging that will reshape the industry. The integration of AI with Internet of Things (IoT) devices is a game-changer. These technologies enable seamless data collection and real-time decision-making, improving your company's overall AI performance and efficiency.

As logistics evolves, the focus will shift to more sophisticated automation. AI will soon handle supply chain processes from start to finish, reducing human involvement in daily operations.

For this to happen, companies will need advanced predictive tools, better risk management systems, and platforms that promote smoother collaboration. The future of logistics is smart, efficient, and largely automated, with AI at its core.

How to Implement AI in a Logistics Operation

To use AI successfully in your logistics business, you need a structured approach with careful planning. Focus should be to balance technology with organisational readiness. Here’s what you can do to implement AI in a logistics operation:

-

Pick a clear business problem: Start with one use case that changes a metric - predictive truck maintenance, demand forecasting, or dynamic route planning.

-

Sort out the data: Map where the needed data lives (TMS, WMS, telematics). Standardise formats, clean obvious errors, and set up a single pipeline so the model sees a consistent feed.

-

Choose the right tool: Off-the-shelf SaaS works for routing and inventory-level forecasts; custom ML might make sense if you already have a data team and unique constraints. Run a time-boxed pilot and measure against today’s baseline.

-

Prepare the people and the process: Train dispatchers, warehouse staff, and drivers on what the model recommends and why. Update SOPs so there’s a clear path for exceptions and overrides.

-

Scale and monitor: When the pilot beats the baseline, roll it out lane by lane. Track accuracy and latency, retrain the model on new data, and keep an eye on drift.

Summing Up

AI is no longer experimental in logistics, it’s a practical way to cut delays, lower costs, and give customers reliable delivery times. Start with one narrow use case, prove the value, then expand. Small wins stack up fast, and the compounding gains set you ahead of competitors who wait.

At GrowthJockey, we help companies implement AI with strategies tailored to their business goals. We understand the challenges faced by Indian logistics companies and create roadmaps that consider local market conditions and regulations.

Contact us for a consultation to discuss your AI in logistics challenges and find implementation opportunities.

FAQs on AI in Logistics

1. How is AI used in logistics?

AI forecasts demand to reduce inventory, optimises routes to cut fuel, automates warehouse picking, and powers autonomous trucks and drones. All this is driven by ML, computer vision, and NLP.

2. What is the future of AI in logistics?

AI in logistics is going to create more autonomous supply chains, where systems manage processes with minimal human involvement. Expect near-autonomous supply chains: specialised agents collaborate, disruption is predicted before it hits, and networks rebalance inventory and routes in real time.

3. What is the best AI for logistics?

The best AI solution for logistics depends on your company’s needs. Companies with advanced data use custom machine learning, while others start with pre-built platforms. The most successful strategies combine targeted solutions and a data plan for future expansion.

4. Is AI used in the supply chain?

Yes! AI now guides procurement, production, inventory, logistics, and customer service, syncing data across functions so decisions stay coordinated and fast.